AFM-IR

delivers nanoscale IR absorption by probing photothermal expansion of sample surfaces

AFM-IR (Atomic Force Microscopy InfraRed) is a family of techniques based on detecting mechanical response of the AFM cantilever upon pulsed illumination of sample with IR light. AFM-IR family includes Tapping and Surface Sensitive AFM-IR, Photoinduced Force Microscopy (PiFM) and Photothermal Expansion Microscopy (PTE, PTIR), primarily utilized for sample absorption mapping and spectroscopy of materials with relatively large absorption coefficient (polymers, organic materials, etc.).

Read the White Paper

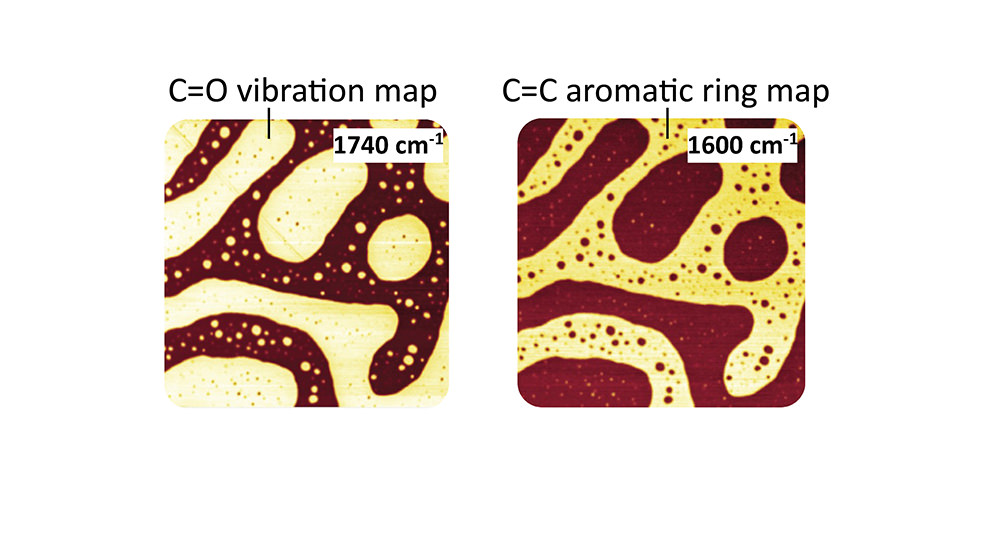

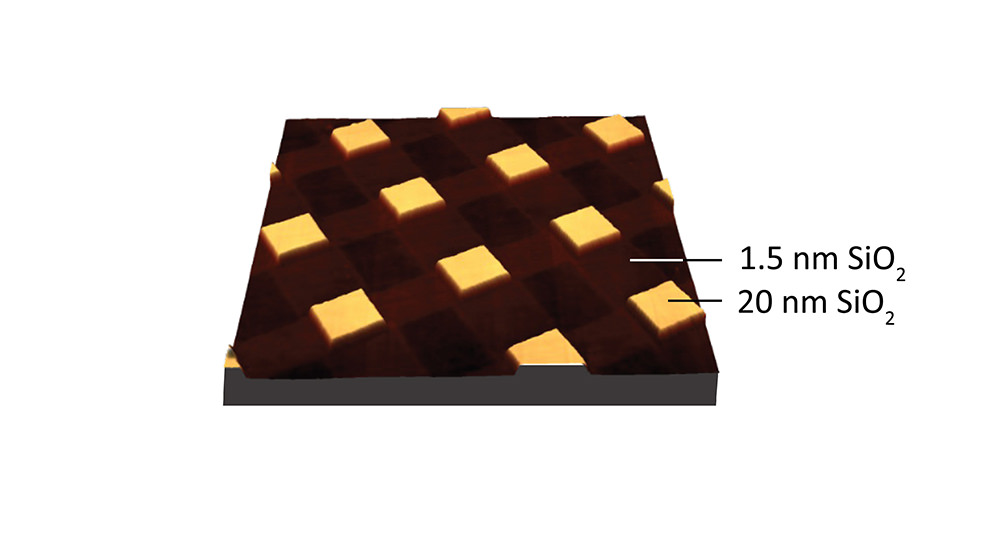

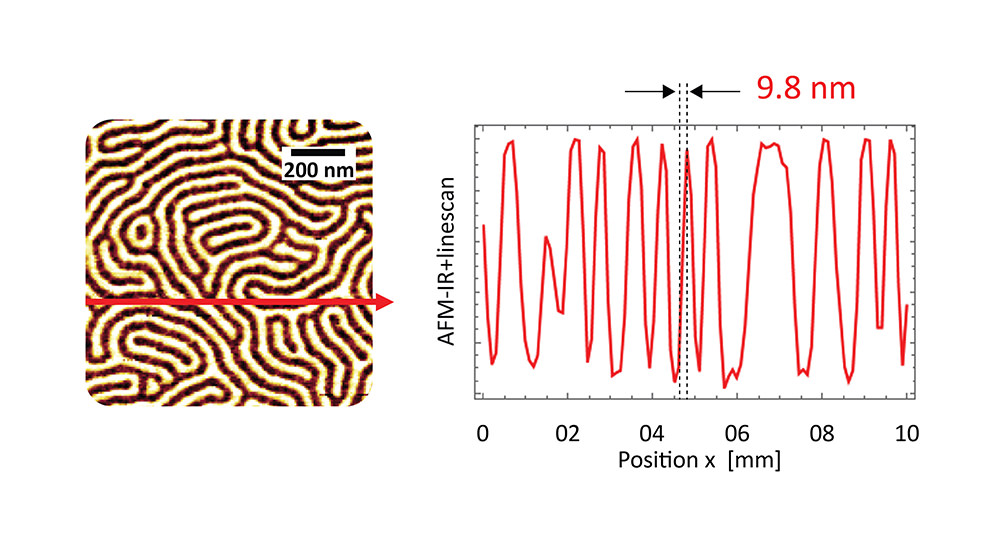

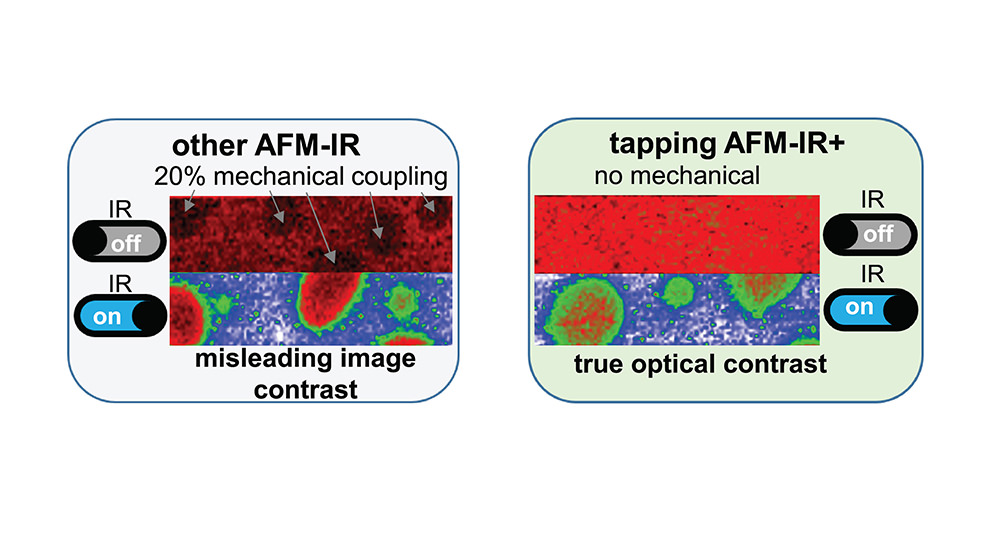

A pulsed laser source is focused on a sample generating photothermal expansion of the absorbing regions near the AFM tip which induces a transient cantilever oscillation proportional to the IR absorption. Patented multimodal detection returns pure infrared absorption maps free of mechanical artifacts – all simultaneously with AFM topography and phase (image size above 10x10 µm).

Technology Benefits

High-quality nanoscale-resolved chemical imaging.

High sensitivity even on ultrathin oxide layers with tapping AFM-IR+.

Sub-10 nm resolution demonstrated on PS-PMMA block copolymer.

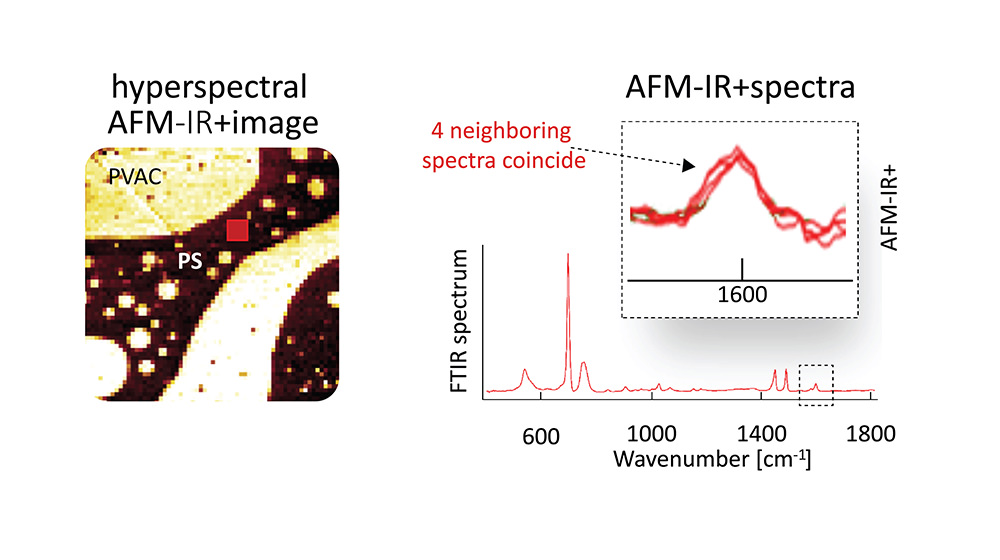

No mechanical artifacts in tapping AFM-IR+ images for true optical mapping & hyperspectral analysis.

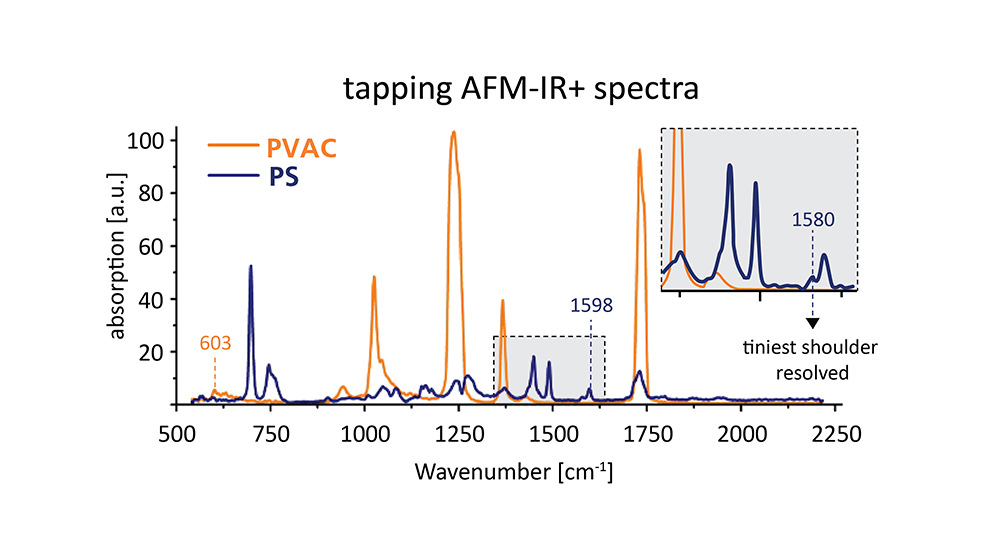

Excellent sensitivity: AFM-IR+ detects even the weakest vibrational signatures for precise chemical identification.

Excellent reproducibility even for the weakest spectral features and fast acquisition speeds.